If you are searching for a 3D printing service in China that is robust and efficient, you can avail yourself of the same from Facfox. Services of 3D printing that you can avail of from Facfox are excellent, and we provide the services with a lot of care and commitment. We are a company that delved into rapid prototyping services in China, and all our employees are adept at rendering flawless services with dedication. Rapid prototyping involves the fast fabrication of any physical parts or model by using computer-aided design (CAD) in 3D. The creation of the part is mostly done using additive manufacturing and is called 3D printing as well.

How Does A 3D Printing Service Work?

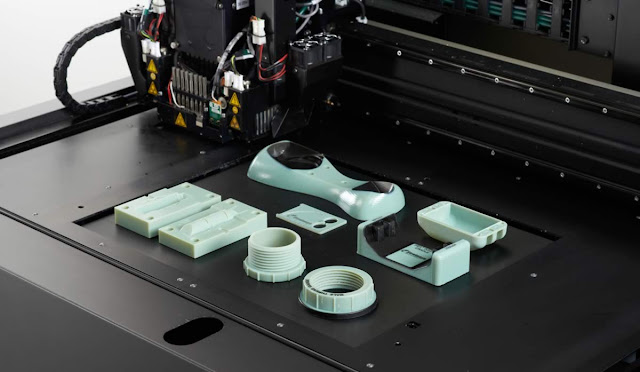

In the process, our professionals subject the material to be printed in a machine that reads the data from the CAD drawing, followed by laying down the successive layers of powder, sheet, or liquid material. It is this material that builds up the physical model from the series of cross-sections.

We put your idea or creation into reality in the form of simple steps. In the metal 3D printing service that our company provides, we upload the 3D files, select the finish of the material, get analysis as well as order followed by producing it. You can then receive the parts in the best form.

For the 3D printing services at our company, we use an interface of data that is standard and can be implemented in the STL format for translating from the CAD software to the 3D prototyping machine.

Advantages Of 3D Printing Services

- This process enables the ability to explore and realize some of the concepts quickly.

- It can apply several repeated designs and incorporate certain changes that enable the evaluation and testing of the products.

- 3D printing services can communicate concepts effectively and concisely. Thus, it takes ideas from images and concepts from visuals of 2D that clients can see into action.

- The process can save money and time since the process does not require tooling and setup.

You can avail of 3D metal printing service from our company by relying on us completely as we are here to help you out with instant analysis. We offer clients versatile material of the industrial grade. You will be able to note a rapid turnaround from our company, and we shall provide you with a future where there is a brilliant idea.