Sheet metal is one of the most adaptable and durable materials in the industry of manufacture. This material has perfectly found its place in the industrial age. Sheet fabrication service is used to prepare significant sheet metals using other essential metals like nickel, copper, tin, brass, aluminum, steel as well as titanium.

Advantages Of Using Sheet Metal

There are several advantages of the sheet metal:-

- The sheet metal is low in gauge as well as weight. This makes it very easy to work with transport and install in different locations.

- Sheet metal is light, efficient as well as high quality. These metals are valuable in terms of the economy.

- The materials formed by sheet metal fabrication are repairable straightforwardly and simply.

What Is Injection Molding?

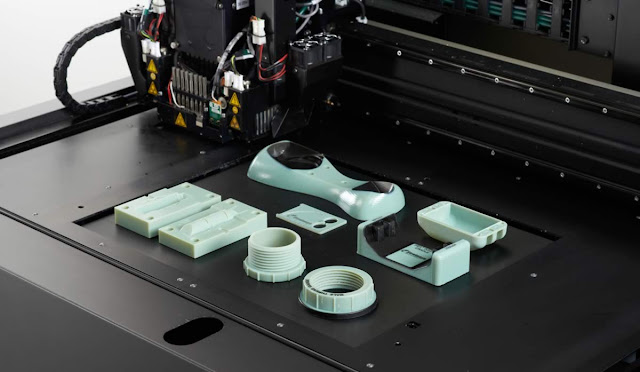

Injection molding Services are standard for preparing models. In this method, the plastic pallets are molded with heat and injected at high pressure into a mold cavity that solidifies to form the final product. The resin pallets are installed into the barrels where they are injected, compressed, and melted into the mold's runner system.

We are known for providing metal injection molding services without any delay in time. There are ejector pins that remove the mold's melted part, and it falls into a bin. When the process is completed, the parts are packed and shipped to different parts of the world.

Backpressure For Injection Molding

The backpressure has to be overcome when the screw is reversed. High backpressure is beneficial for dispersion of the pigment and thermoplastic Injection Molding, but it also increases the time of screw retraction. This pressure also reduces the size of the plastic fiber and increases the machine's pressure that performs injection molding.

When the foam of plastic is inserted, the backpressure must be higher than the gas else the screw will come out. Due to the coming out of the screw, it becomes difficult to adjust the machine.

Our company is known for its rapid prototyping plastic injection molding. Our company is devoted to creating and connecting premium manufacturing services and providing affordable price as well as quality to international customers. We help the customers to turn their innovative idea into effective products with quality tools.