While there are manufacturing technologies, injection molding is one such process that enables the production of the smallest components to whole parts. As the term suggests, the process involves injecting molten material into molds. These molds are primarily made up of steel or aluminum.

Injection molding services are of significant importance in the manufacture of a wide array of parts and prototypes. Apart from thermoplastics, metals are also used in the process. Once the molten material is inserted into a mold, it is allowed to cool and solidify before removing it from the mold. The products obtained generally do not require post-processing until a customized surface finish is demanded.

The Process of Injection Molding

It can be said that plastic injection molding services are a lot less complex processes when compared to other manufacturing techniques. No matter whatever be the size of the designed product, injection molding can be implemented anywhere.

In the process, a mold is created from aluminum or steel that is placed inside the machine and adjusted with clamps. Molten plastic or metal is injected into the mold with the aid of pressure and heat. The material is allowed to cure and is finally taken out of the mold.

Thus, injection molding technology is a hassle-free manufacturing process that demands lesser lead time and the execution of too many tools. It is a rapid production process intended to meet large scale demand.

Apparent Benefits

Injection molding services offer some of the most prominent advantages that are observed in various fields. These are:

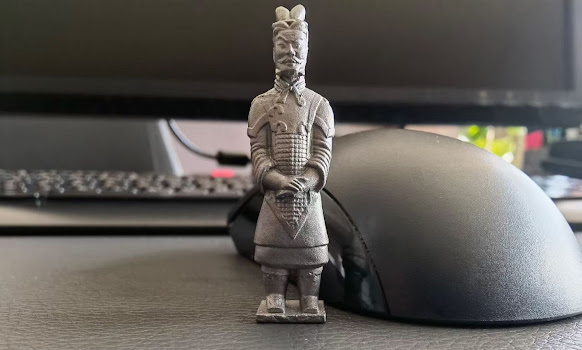

- It is possible to achieve highly complex and uniform product designs through metal injection molding services.

- With the faster rate of production, this process stands out to be one of the most efficient molding technologies in the industry.

- There are endless possibilities of choosing materials- color and texture that makes injection molding greatly flexible.

- The end-products are immensely durable and possess consistent strength and quality.

- Since the procedure is entirely automated, there is reduced labour cost.

- Minimal material wastage is also a major advantage of injection molding technology.

Thus, sophisticated parts with a rapid production rate- injection molding services are the best solution!